Types of Winding Machines?

Types of Winding Machines?

Companies that are operating in the paper and textile industries often use several kinds of enormous spools of material in their daily business activities. Isn’t it questionable how an enormous amount of material gets fixed onto the spools for the first time? If you are also curious to know what it is, the answer is winding machines. Winding machines help the paper and textile industries to quickly wrap paper, fabric, cord, yarn, tape, twine, thread, wire, string, rope, and many more and offer industrial-sized spools to the textile manufacturer as needed. There are several kinds of winding machine applications that you can choose from when you are looking for a winding machine based on your requirements. Mainly, winding machines are classified as per the type of material being wound and spooled, like spool machines, paper winding machines, film winding machines, rope winding machines, foil winding machines, and so on. Alidhra Weavetech offers three major types of winding machines, which can be an ideal choice for the textile industry. Read this blog carefully to find out the work and product information of the Weavetech winding machine briefly:

Pirn / Cops Winder Machine

- Cop Winding Machine: Cop winding machine is basically used by the textile industry to supply the weft yarn and wind jute. This machine has four heads, which improves its functionality and helps in winding four cops at one time. One of the effective features of a cop winding machine is its clamps, which help the machine to control the overall length of the yarn. Here, the size and shape of the cop can be easily adjusted as per requirements. A necessary amount of pressure is needed here instead of bobbins or tubes. Weavetech has solutions for all kinds of textile machinery, whether it is twisting or weaving. You can connect with us to find out more about the product features and its price structure.

- Pirn Winding Machine: Pirn winding machines are available in two types, i.e., ordinary pirn machines and automatic pirn machines.

Both the machines are effective for winding silk, wool, cotton, nylon, and synthetic polyethylene fibre yarns. This machine mainly consists of four spindles, and two machines can be joined together to obtain eight spindles. Get in touch with Weavetech to know about the role and effectiveness of pirn winding machines in the textile manufacturing industry.

There are some differences between cops and pirn winding machines as they are both used for different purposes. One of the major differences is that the weft package in the pirn winding machine is cotton while the weft package in the cop winding machine is jute. Furthermore; cop winding machines enable the winding of four cops only at one time, while pirn machines enable the winding of more than four pirns at a time.

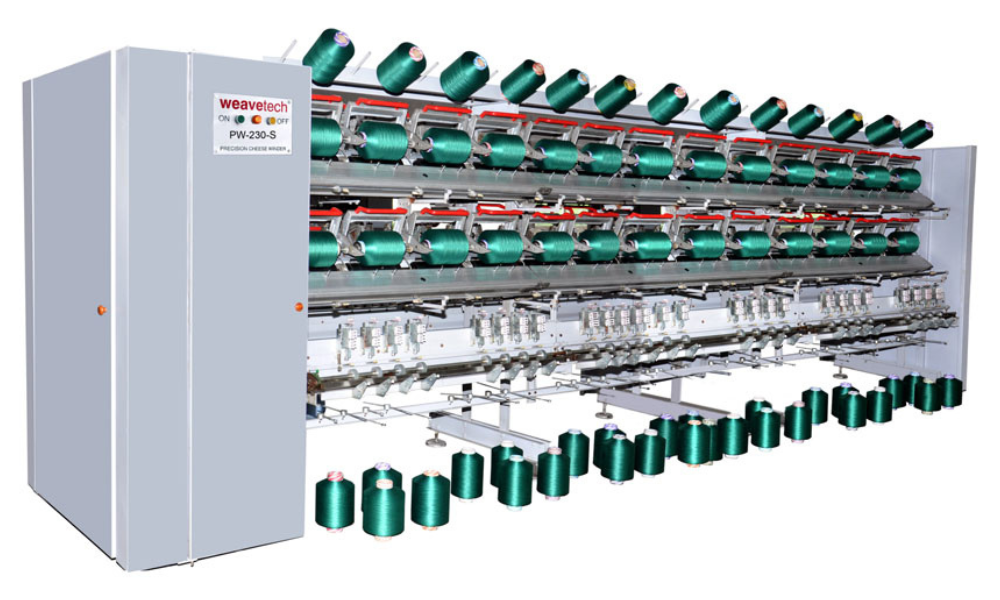

Precision Assembly Winder

Compared to a traditional yarn watching machine that basically uses a groove drum yarn guide, the AW22 precision assembly winding machine uses electricity and yarn guide technology to complete the process. This winding machine is used for close-knit winding of short fibres such as; cotton, wool, cotton and wool together, and spandex as well. It also has one excellent feature, which is reversal during the twisting process. Weavetech deals with two major kinds of precision assembly winders across India,

i.e., Universal Winder UW-1 and Bobbin Winder ABW-10.

The Universal Winder UW-1 is mainly used for the Preparation of assembly wound packages of multi-ply filament yarns of 3–10 kg for the next twisting process. The denier range of this machine is almost 400–18000 denier filament yarns and up to 20 ply with a ply sensor and auto-stop system.

On the other hand, Bobbin Winder ABW-10 is being used for the preparation of assembly wound packages on the Bobbin Winder of multi-ply filament yarns of 3-5 kg for the next twisting process. This also ensures that all plys stay and unwind together for smooth operations. This also enables a fully programmable speed and a mechanically adjustable winding ratio. The ply range of this winding machine model is up to 20 ply with a Dropbox sensor and an Auto-Stop system with up to 300 metres per minute speed. Get in touch with Weavetech to leverage the best and most effective winding and twisting solutions across the nation.

Dye Package Winder

Dyed winding machines are being used by textile manufacturers across the globe for winding fine to coarse denier filament yarns that are used for both weaving and knitting. Here, both the thread and yarn winding machines are suitable for rewinding large packages into smaller packages for the further downstream processes. Furthermore, a soft winder is used for the preparation of soft packages for dyeing and a hard winder is used for the final winder for the preparation of hard packages post dyeing. The denier range of this model is around 30 to 600 denier filament yarns along with 20 to 150 denier monofilament yarns. The maximum speed of the dye package winder is up to 1200 m/h. Weavetech has all the twisting and winding solutions, hence is considered as one of the most famous and well-known textile manufacturers in India.

You can connect with us to find out more about our products and services in the textile industry and what makes us stand out from the crowd. Traditionally, the core competency of WEAVETECH lies in its ability to understand specific customer needs and respond to those needs with highly customized solutions. The result is the world’s largest range of TFO Twisting machines to offer you the best possible value for your investment.