Common Sewing Machine Bobbin Problems And Solutions

Common Sewing Machine Bobbin Problems And Solutions

What is a bobbin?

A bobbin is a part of the sewing machine on which the lower thread is wound. The machine makes a stitch by catching the bottom thread, from the bobbin, with the top thread, from the needle.

What is a bobbin winder?

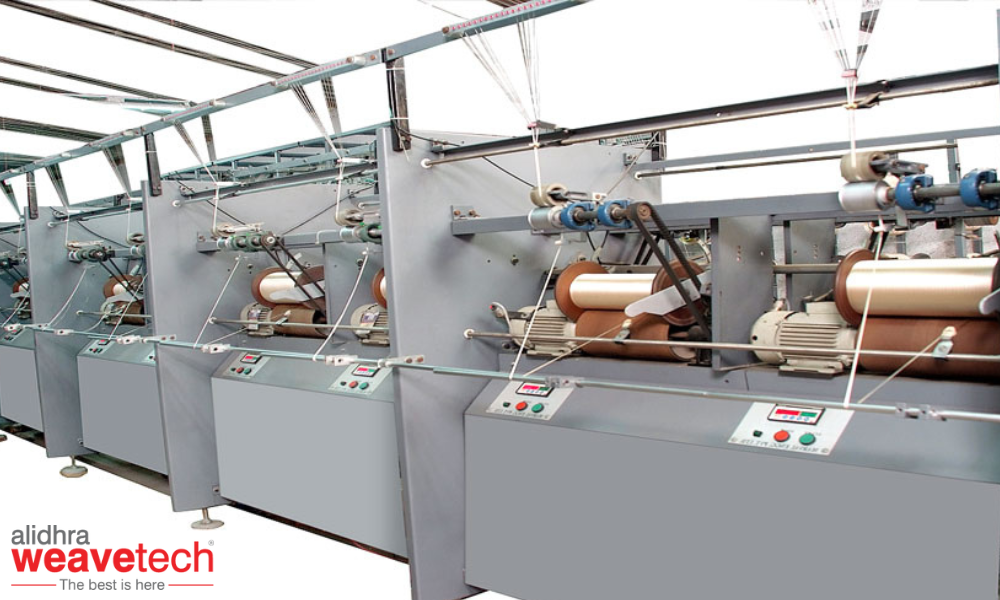

A bobbin winder is a device that is used to wind thread or yarn onto a bobbin, which is a small, spool-shaped device used in sewing and other textile arts. Bobbin winders can be manual or electric and are often found on sewing machines or as stand-alone devices. They are used to create a smooth or even winding of thread onto the bobbin, which is necessary for smooth and consistent sewing. If you are looking for bobbin winder machine visit Alidhra Weavetech, we produce a variety of winding machines to make sure you’re able to weave fabric out of the best quality yarn. Our Bobbin Winder Machine ‘Bobbin Winder ABW-10’ is an assembly bobbin winder, designed for the carpeting and furnishing segments of the textile industry.

Bobbin winder tension disk

A bobbin winder is a small adjustable component found on some sewing machines. It is used to control the tension of the thread as it is wound onto the bobbin. By adjusting the tension disk, the user can ensure that the thread is wound onto the bobbin evenly and tightly, which can help prevent tangling and improve the quality of the sewing. The location and the design of the tension disk can vary depending on the specific sewing machine model.

Bobbin winder stopper

A bobbin winder stopper is a small component found on some sewing machines that is used to stop the bobbin from winding too much thread into it. The stopper is typically located near the bobbin winder and can be adjusted to the desired amount of thread. Once the bobbin reaches the stopper, the winding process will stop, preventing the bobbin from becoming overfilled with thread. This helps ensure that the bobbin is wound with the proper amount of thread, which can improve the quality of the sewing and prevent tangling.

Bobbin problems are a common issue faced by sewing machine users. These problems can range from the bobbin not winding properly to the thread becoming tangled or jammed.

Here Are Some Common Bobbin Problems And Their Solutions:

Bobbin thread getting tangled:

This is often caused by the bobbin being inserted incorrectly or the bobbin case being dirty. To fix this, make sure the bobbin is inserted correctly and clean the bobbin case.

Bobbin thread bunching:

This can happen when the bobbin tension is too tight or the bobbin is not inserted correctly. Adjust the bobbin tension and re-insert the bobbin correctly to fix the problem.

Bobbin thread breaking:

This can happen if the bobbin is old or damaged, or if the machine is not properly threaded. In order to fix this, replace the bobbin with a new one and make sure the machine is properly threaded.

Bobbin not winding properly:

This happens when the bobbin winder is not engaged or if the thread is not properly inserted through the tension guide. To correct this, engage the bobbin winder and make sure the thread is properly inserted through the tension guide.

Bobbin case not locking:

If the bobbin case is not properly aligned or if the machine is not properly threaded, the bobbin case does not lock. You need to properly align the bobbin case and make sure the machine is properly threaded in order to correct this problem.

There are several steps you can take to resolve an issue with a bobbin winder not working properly.

- Verify that you are using the correct bobbins.

- Check the threading by making sure that the thread is properly threaded through the machine, including the tension discs.

- Check the bobbin and if it is inserted correctly and that the thread is not tangled or caught on the bobbin.

- Make sure the tension on the machine is set correctly. This can often be adjusted using a dial or knob on the machine.

- Investigate whether there are scratches or other defects on the bobbin. Replace the bobbin if in doubt.

- Check if the needle is not bent or damaged, and that it is inserted correctly in the machine.

- Check the power supply, if you are using an electric bobbin winder, make sure the machine is plugged in and the power switch is on.

- Make sure you clean the machine. Lint and dust can accumulate in the machine over time and can cause issues with the bobbin winder. Clean the machine thoroughly, paying special attention to the bobbin case, tension disks, and other moving parts.

- If the machine is still not working properly, it may need to be serviced by a professional technician.

- Refer to manual if you are still not able to resolve the issue for more detailed troubleshooting steps and instructions specific to your machine.

By understanding the common problems and solutions, you can keep your sewing machine running smoothly and avoid interruptions in your sewing projects.

Weavetech offers the best yarn weaving machines, winding machines, and twisting machines all over India. Therefore, if you are looking for the best textile machinery manufacturer in India, then don’t look further and get in touch with Weavetech today.