Major Problems and Solutions in Rapier Loom Weaving

Major Problems and Solutions in Rapier Loom Weaving

In the heart of the textile industry lies the intricate art of rapier loom weaving—a process that weaves together threads of tradition, innovation, and craftsmanship to create fabrics that adorn our lives. From the bustling factories of urban centers to the quaint workshops tucked away in rural landscapes, rapier loom weaving serves as a testament to human creativity and ingenuity. However, amidst the rhythmic clatter of looms and the gentle hum of machinery, challenges abound, threatening to disrupt the seamless flow of production. Shedding irregularities, yarn breakage, weft insertion problems, maintenance challenges, and quality control issues loom large, casting shadows of uncertainty over the weaving process.

But fear not, for within these challenges lie opportunities for growth and improvement. With a keen eye for innovation and a steadfast commitment to excellence, textile manufacturers can navigate the complexities of rapier loom weaving and emerge stronger and more resilient than ever before.

In this comprehensive guide, we’ll embark on a journey through the major problems faced in rapier loom weaving and explore practical solutions to ensure smooth sailing for textile manufacturers. From shedding issues to quality control concerns, we’ll delve deep into the intricacies of weaving technology and provide actionable insights to overcome hurdles and unlock new levels of production efficiency.

1. Shedding Issues

Shedding irregularities, characterized by uneven shed formation, pose a significant challenge in rapier loom weaving. This can result in broken threads, tension discrepancies, and ultimately, compromised fabric quality. To address shedding issues effectively, textile manufacturers must focus on optimizing shedding mechanisms and maintaining proper warp and weft yarn selections.

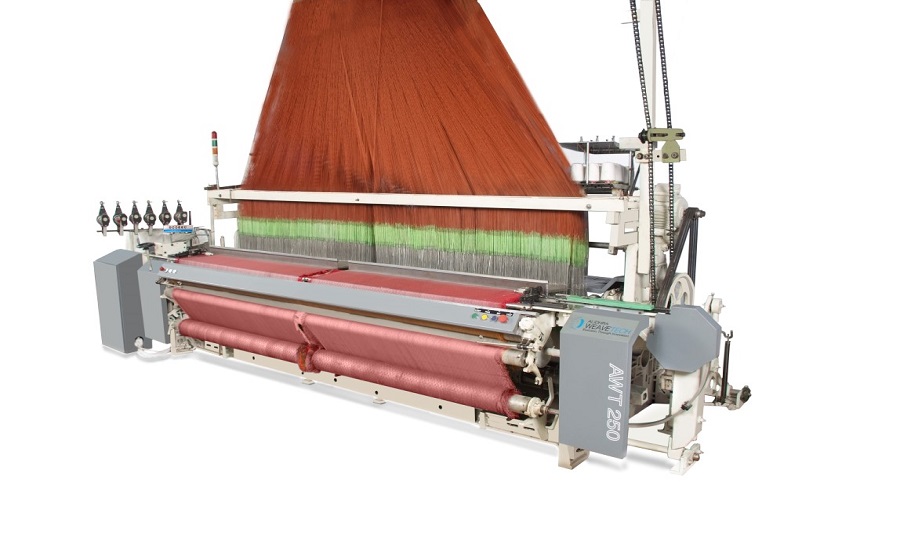

At Weavetech, we understand the importance of shed consistency in achieving optimal weaving performance. Our cutting-edge rapier looms are equipped with advanced shedding technology, ensuring precise shed formation and minimizing the risk of weaving defects. By investing in Weavetech’s innovative solutions, manufacturers can mitigate shedding problems and enhance overall production efficiency.

2. Yarn Breakage

Yarn breakage during weaving is a common concern that can disrupt production flow and lead to costly material waste. Factors such as yarn tension, yarn quality, and loom speed settings play crucial roles in preventing yarn breakage. At Weavetech, we provide comprehensive solutions to address yarn breakage challenges, including customizable loom configurations, quality yarn recommendations, and expert technical support.

By partnering with Weavetech, manufacturers gain access to a wealth of resources aimed at optimizing weaving processes and minimizing downtime. Our team of experienced professionals works closely with clients to identify potential areas for improvement and implement tailored solutions that maximize yarn integrity and weaving efficiency.

3. Weft Insertion Problems

Efficient weft insertion is essential for achieving uniform fabric quality and minimizing weaving defects. However, challenges such as selvage irregularities and pick density variations can arise if weft insertion parameters are not properly calibrated. Weavetech offers state-of-the-art rapier looms equipped with advanced weft insertion technology, ensuring precise and consistent fabric formation.

Through our collaborative approach to customer support, Weavetech assists manufacturers in fine-tuning weaving parameters to optimize weft insertion efficiency. Our technical experts provide comprehensive training programs and ongoing assistance to empower operators with the knowledge and skills needed to maintain optimal weaving conditions.

4. Loom Maintenance Challenges

Neglected maintenance can lead to mechanical failures, reduced loom efficiency, and increased downtime, posing significant challenges for textile manufacturers. To mitigate the risk of maintenance-related issues, Weavetech emphasizes the importance of proactive maintenance practices and operator training.

Weavetech’s comprehensive maintenance programs are designed to prolong the lifespan of rapier looms and optimize production output. By implementing regular cleaning, lubrication, and inspection protocols, manufacturers can prevent potential breakdowns and ensure the uninterrupted operation of their weaving equipment.

5. Quality Control Issues

Maintaining consistent fabric quality is paramount in the textile industry, yet quality control issues can arise due to weaving defects and inconsistencies. Weavetech offers innovative solutions to address quality control challenges, including real-time monitoring systems and automated inspection technologies.

Through our partnership with Weavetech, manufacturers gain access to cutting-edge quality assurance tools and techniques that enable them to detect and rectify defects early in the production process. By implementing rigorous testing protocols and leveraging advanced inspection technologies, manufacturers can uphold the highest standards of fabric quality and customer satisfaction.

Rapier loom weaving presents a myriad of challenges, from shedding issues to quality control concerns. However, with Weavetech’s innovative solutions and unwavering commitment to customer success, textile manufacturers can overcome these hurdles and achieve unparalleled levels of production efficiency and fabric quality.

As a leading provider of rapier loom technology, Weavetech is dedicated to empowering manufacturers of Textile Machineries with the tools and expertise needed to thrive in today’s competitive market. Through our comprehensive range of solutions and unparalleled customer support, we ensure that every weaving operation operates at peak performance, delivering superior fabric outcomes with confidence and ease.

Ready to overcome the challenges of rapier loom weaving and unlock new levels of production efficiency? Contact Weavetech today to learn more about our cutting-edge solutions and how we can help optimize your weaving processes for success. Let’s embark on a journey towards seamless production together.